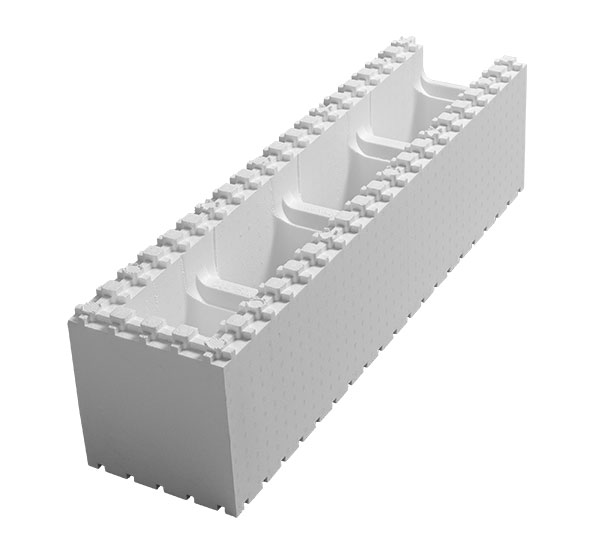

Edge thermal block EPS 90 (250x1000x250)

Almost identical to the standard thermoblock, but with the difference that one of the ends is completely blank. The thickness of walls, the number of lintels and the structure for connection are the same as in the standard block. Scope of application - the formation of window and door openings, as well as - corners.

Thermoblocks are made of polystyrene EPS 120 in accordance with DSTU B.V.2.7-8-94 for the construction of houses according to DBN B.2.6-6-95.

All the products are manufactured exclusively at the production facilities of the company in Kyiv, which guarantees compliance with the high quality standards of "Valkyria" at all stages, as well as providing the product with all the necessary documentation.

Functionally EPS 120 thermoblocks differ from EPS 120 only in their density. Other characteristics and advantages, due to which consumers for 14 years have preferred thermoblocks produced by "Valkyria" remain the same.

Main advantages of thermal blocks TM "Valkyria" EPS 90

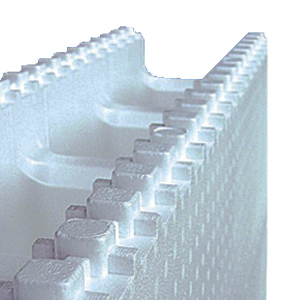

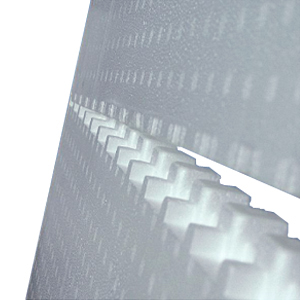

The "spike-groove" lock

This connection in one row ensures that there are no leaks. There are specially configured locks on the top and bottom of the unit walls to ensure no displacement and a tight joint. This jointing system is ideal for maintaining project-specific geometric dimensions and wall impermeability.

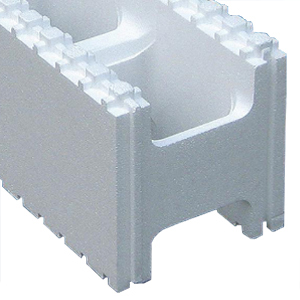

Deep side lock "groove-ridge"

Another important component of the block construction. This lock allows the blocks to be securely joined together in a row, eliminating the possibility of concrete leakage.

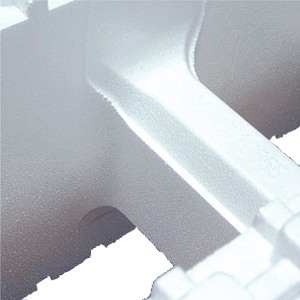

Lintel

The radius shape of the lintel connection to the block wall is a unique feature for Valkyria thermoblocks. Thanks to this the area of adjacency increases. That is, the block becomes as resistant to rupture as possible when pouring concrete.

Density

Valkyrie's production facility and high quality control standards guarantee that the declared density for thermoblocks is 25 kg/cubic meters.

Geometry

Ideal geometry is a calling card for TM Valkyria`s thermoblocks. Thanks to the automation of production and the absence of human factor, the wall erected from such thermoblocks is perfectly straight.

Counterfeit protection

The designation of the site and phone number of the manufacturer makes it possible to identify the originality of the product, protecting it from counterfeit.

Limitations when using the thermoblock TM "Valkyria" PSV_C 25

1. Concrete pouring speed.

The density of polystyrene foam in the thermoblock 25 kg / cu.m. limits the speed of erection of the wall. This is the key difference. Thus, we recommend the use of PSV_CS 25 thermoblocks only for individual (private) construction of houses with the number of stories up to 3 floors inclusive. In this case the height of wall, which is filled with concrete when using such a block shall not exceed 0,5 m. (2 blocks) per day

2. The need to observe extra precautions when transporting blocks to the site.

When unloading and loading work thermoblocks with density of 25 kg/cu.m. require careful handling. We recommend to carry out such work only by hand. With further storage and use at the construction site there is no need for special measures (except for mandatory protection from sunlight during prolonged storage on the street).

IMPORTANT: Valkyria`s products are patented, therefore, similar products offered by other companies and individuals may not meet all requirements and may be counterfeit. Our customers should pay attention to the special marking with our details on the block, as well as require a dealer's certificate from the seller (in case of purchasing blocks not in the office of Valkyria LLC).