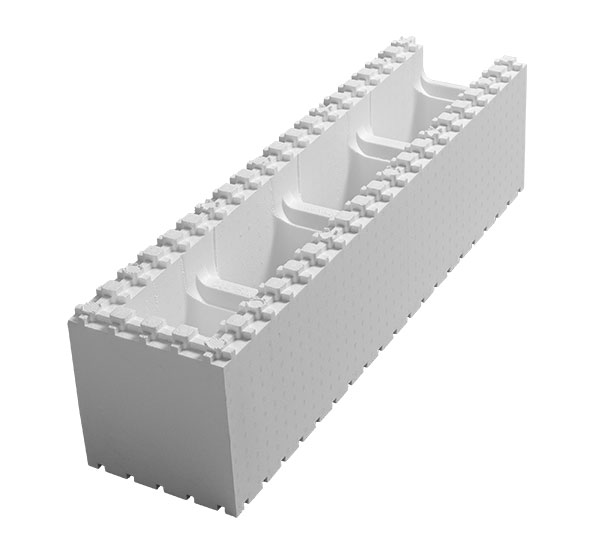

Edge thermal block EPS120 (250x1000x250)

This block consists of two walls (each 50 mm.), joined together by polystyrene foam lintels.

This block consists of two walls (each 50 mm.), joined together by polystyrene foam lintels.

One end of the block is completely blank.

It is used in the formation of corners, windows and door openings.

Main advantages of thermal blocks TM "Valkyria" EPS120

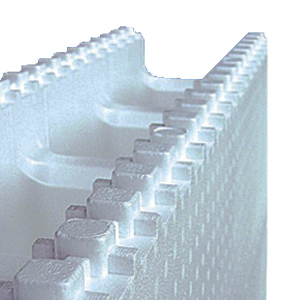

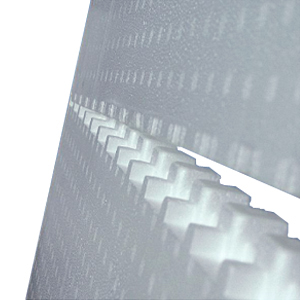

The "spike-groove" lock

This connection in one row ensures that there are no leaks. There are specially configured locks on the top and bottom of the unit walls to ensure no displacement and a tight joint. This jointing system is ideal for maintaining project-specific geometric dimensions and wall impermeability.

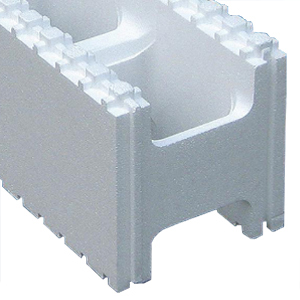

Deep side lock "groove-ridge"

Another important component of the block construction. This lock allows the blocks to be securely joined together in a row, eliminating the possibility of concrete leakage.

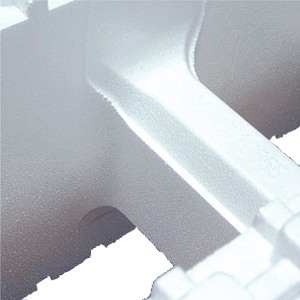

Lintel

The radius shape of the lintel connection to the block wall is a unique feature for Valkyria thermoblocks. Thanks to this the area of adjacency increases. That is, the block becomes as resistant to rupture as possible when pouring concrete.

Density

Valkyrie's production facility and high quality control standards guarantee that the declared density for thermoblocks is 35 kg/cubic meters.

Geometry

Ideal geometry is a calling card for TM Valkyria`s thermoblocks. Thanks to the automation of production and the absence of human factor, the wall erected from such thermoblocks is perfectly straight.

Counterfeit protection

The designation of the site and phone number of the manufacturer makes it possible to identify the originality of the product, protecting it from counterfeit.