Production

One of important factors defining our position in the market of building services is own production. It shall be clear how much more dynamic is interaction with our partners when import of elements of structures from abroad is not required.

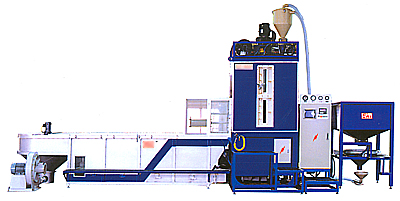

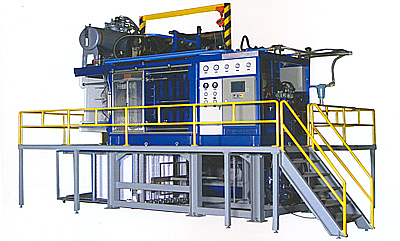

Situation in the building materials and services market made us sure in the necessity of continuous development of own production facilities. In 2006, we have completely modernized equipment, the cost of which them amounted to over 500 thous. USD. In 2008, we have additionally expanded our facilities having purchased advanced automatic molders. It allowed us to increase our production facilities twice, thus bringing production of thermal blocks up to 1.5 mln. pcs. per year.

Production plant in the capital of Ukraine is safe, comfortable and profitable for us and builders.

Qualified personnel with long working experience guarantees output of quality products with the obligatory quality control and testing each item by many parameters. Only highest quality thermal blocks and expanded foam arrive at the finish products storehouse. Polystyrol manufactured by the leading manufacturers from Korea, Germany and Poland is used for production. By its physical and mechanical properties it outstrips by far domestic equivalents.

Polystyrol is a light-weight cellular material that consists of atoms of hydrogen and carbon. There are two commonly known types of polystyrol: extruded polystyrol and foamed-self-damping one (PSV-S). for production of thermal blocks and sheet expanded polystyrene foam we use polystyrol PSV-S. it is made of polystyrol balls that contain gas-forming agent and flame-proof additives. The heat of vapour affects gas-forming agent, as a result of which semi-finished balls appear that increased in size approximately 10–12 times at the time of processing.

Polystyrol is a light-weight cellular material that consists of atoms of hydrogen and carbon. There are two commonly known types of polystyrol: extruded polystyrol and foamed-self-damping one (PSV-S). for production of thermal blocks and sheet expanded polystyrene foam we use polystyrol PSV-S. it is made of polystyrol balls that contain gas-forming agent and flame-proof additives. The heat of vapour affects gas-forming agent, as a result of which semi-finished balls appear that increased in size approximately 10–12 times at the time of processing.

After the intermediate stage, during which balls get free of moisture, gas-forming agent condenses, while air penetrates into porous surface. After air stabilization previously enlarged balls are fed to moulds for production of PSV-S goods, where products are finally molded by means of vapour heat.

In the process of production an important factor of the quality of thermal blocks is density of expanded polystyrene foam. It is very important for blocks production as in the process of construction , at the moment of pouring concrete on blocks, pressure on block’s walls from inside is generated. If density of thermal blocks is too small, concrete can merely tear them to pieces. The higher is the density of thermal blocks, the more durable they are. The density of polystyrol at thermal blocks production is 35 kg/cub. m. It allows builders not to interrupt pouring of concrete on blocks at the height of up to 1.5 m.

Sheet expanded foam is produced with various density values–15, 25, 35 and 50 kg/cub. m, thickness - from 20 mm depending on intended purpose – heat insulation foundations, floors, walls, roofs.

The entire production cycle is closed. All operations related to products manufacturing are performed under the same roof. Production я power of the plant is 150 thous. cub. m of expanded foam and 1.5 mln. thermal blocks per year.

The acquired experience, quality of raw materials, production facilities and uninterrupted operation with continuous improvement of all aspects of the plant’s activities brought to expected results. We are able to fully satisfy demand for our products. We work for our customers in timely, quality and effective manner.