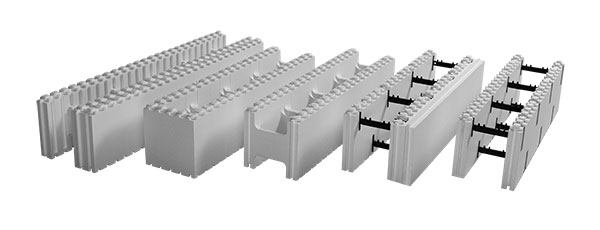

Specifications of thermal blocks

For production of thermal blocks of PSV-S type polystyrol (foaming-self-damping expanded polystyrene foam) of leading world manufacturers from Korea, Germany, and Poland is used. By its physical and mechanical properties this polystyrol outstrips by far domestic equivalents.

PSV-S does not contain chloro-fluocarbons or incompletely halogenated chloro-fluocarbons. It is an environment-friendly material is not harmful for human body used of production of disposable tableware, package for food products and the like.

Expanded polystyrene foam burns under the influence of a quite strong heating source. However, in a house there are always many materials capable of inflame at lower temperatures as compared with expanded polystyrene foam, which is reflected in the table given below.

Besides, to reduce the possibility of accidental inflammation all articles made of polystyrol PSV-S contain flame-proof additives, which are added at production.

Such special additives help to prevent inflammation of the material from small fire sources, such as, for example, matches or lit up cigarettes. It is an important factor of fire safety.

| Name of product | NEW!!! Block EPS ordinary EPS 90 (M - 25) "100х50" | NEW!!! Block EPS ordinary EPS 120 (M - 35) "100х50" | Block EPS ordinary/сorner EPS 90 (M - 25) | Block EPS ordinary/сorner EPS 120 (M - 35) | Block EPS, folding EPS 90 (M - 35) "50х50" | Block EPS, folding EPS 120 (M - 35) "100х50" |

| The actual density of polystyrene foam | 15,1-16 kg/m3 | 21,1-22,0 kg/m3 | 15,1-16 kg/m3 | 21,1-22,0 kg/m3 | 21,1-22,0 kg/m3 | 21,1-22,0 kg/m3 |

| Geometric sizes, mm | 1250*300*250 | 1250*300*250 | 1000х250х250 mm | 1000х250х250 mm | 1000х(200-550)х250 | 1000х(200-600)х250 |

| Polystyrene foam wall thickness | 50 мм + 100 мм | 50 мм + 100 мм | 50 mm + 50 mm | 50 mm + 50 mm | 50 mm + 50 mm | 50 mm + 100 mm |

| Internal distance between expanded polystyrene boards | 150 мм | 150 мм | 150 mm | 150 mm | 100 mm - 450 mm | 100 mm -450 mm |

| Thermoblock weight | 0,95 kg | 1,3 kg | 0,5 kg | 0,75 kg | 1,2 kg | 1,45 kg |

| Jumper weight | - | - | - | - | 0,07 kg/pcs | 0,07 kg/pcs |

| Concrete consumption | 0,13 m3/m2 | 0,13 m3/m2 | 0,13 m3/m2 | 0,13 m3/m2. | 0,1-0,45 m3/m2. | 0,1-0,45 m3/m2. |

| Finished wall weight | 325 kg/m2 | 325 kg/m2 | 325 kg/m2 | 325 kg/m2 | 250 - 1125 kg/m2 | 250 - 1125 kg/m2 |

| Thermal conductivity, λ | 0,037 W/m∙K | 0,033 W/m∙K | 0,037 W/m∙K | 0,033 W/m∙K | 0,037 W/m∙K | 0,033 W/m∙K |

| Vapor permeability | 0,032 mg/(m.h.Pa) | 0,032 mg/(m.h.Pa) | 0,032 mg/(m.h.Pa) | 0,032 mg/(m.h.Pa) | 0,032 mg/(m.h.Pa) | 0,032 mg/(m.h.Pa) |

| Water absorption (24 hours) | < 2% | < 2% | < 2% | < 2% | < 2% | < 2% |

| Self-extinguishing time | < 2 sec | < 2 sec | < 2 sec | < 2 sec | < 2 sec | < 2 sec |

| Flammability group | Г1 | Г1 | Г1 | Г1 | Г1 | Г1 |

| Acoustic insulation | 46 db | 46 db | 46 db | 46 db | 46 db | 46 db |

TABLE 1. INFLAMMATION TEMPERATURE OF TRADITIONAL HOUSEHOLD MATERIALS.

|

Description |

Temperature of inflammation that occurred as a result of a burst of flame, ˚С * |

Auto-ignition temperature, ˚С ** |

|

Paper |

220 |

230 |

|

Pine needles |

228-264 |

260 |

|

Cotton |

230-266 |

254 |

|

Wool |

200 |

|

|

PVC |

391 |

454 |

|

Polystyrol |

345-360 |

488-496 |

|

Expanded polystyrene foam |

346 |

491 |

* Temperature of inflammation that occurred as a result of a burst of flame is the temperature, at which are formed vapours, which, when mixed with air, may inflame from an external flame source.

** Auto-ignition temperature is the temperature at which material smoldering or inflammation occurs without any external flame source.

All organic chemical materials, including plastic, wood and paper, wool and cotton, release various toxic products, including carbon oxide, when burning. At fire it is the most dangerous gas. Burning of the above-listed organic materials may also result in oxygen deficiency. Knowledge of the chemical composition and structure of organic materials provide grounds for understanding reasons of smoke formation and toxic gases at burning. The majority of materials subject to inflammation contain carbon, therefore at burning they oxidize and release carbon dioxide (СО2). If the oxidizing process is not complete enough carbon oxide (СО) is released. The concentration CO in air equal to 0.3% or 3000 PPM (parts per million) at exposure to it within 30 minutes is dangerous for human beings. Polystyrol heated to 300 ˚С releases 10 РРМ of carbon oxide only ; up to 400 ˚С –50 РРМ only; up to 500 ˚С –500 РРМ only; and when heated up to 600 ˚С it releases 1000 РРМ of carbon oxide.

Taking into account the mentioned above parameters, one can easily testify safety of our products, as well as safety if expanded polystyrene foam as a whole.