Swimming Pool Construction Technology

Construction of swimming pools using thermoblocks has a number of significant advantages compared to traditional concrete or composite pools.

- The pool shell has excellent thermal insulation properties. Since the walls and bottom of the pool are insulated, water heating occurs much faster than in a conventional pool shell. There is no need to heat the walls or the floor slab — only the water is heated. The same effect, but in the opposite direction, is observed during water cooling. As a result, heating costs are reduced and the swimming season in a private pool is extended.

- Due to the elasticity of the pool walls, there will be no future issues related to thermal loads and, as a consequence, cracking that may occur due to frost in monolithic concrete structures.

- Expanded polystyrene absorbs very little water and does not promote the growth of mold, fungi, or any bacteria.

- The ideal geometry of the blocks and the special tongue-and-groove locking system make it possible to achieve smooth and even pool walls.

- Construction of a pool shell from thermoblocks does not require professional building skills. The blocks are assembled according to the LEGO principle; reinforcement is placed inside and then filled with concrete.

Technical specifications:

|

Name |

Standard/End Block EPS 90 |

Standard/End Block EPS 120 |

Modular Block EPS 120 |

|

Geometric dimensions |

250×1000×250 |

250×1000×250 |

250×1000×250 |

|

Polystyrene grade |

M25 |

M25 |

M35 |

|

Polystyrene wall thickness |

2 pcs × 50 mm |

2 pcs × 50 mm |

2 pcs × 50 mm |

|

Concrete thickness (internal distance between walls) |

150 mm |

150 mm |

Adjustable 150–450 mm |

|

Concrete consumption |

0.13 m³/m² |

0.13 m³/m² |

0.15–0.45 m³/m² |

|

Water absorption (within 24 hours) |

0.5% |

0.5% |

0.5% |

Why use thermoblocks for pool construction?

The insulated polystyrene walls and floor help water heat up faster and cool down slower. This saves energy and extends the swimming season.

Are these pools resistant to frost and temperature changes?

Yes. The elasticity of polystyrene prevents cracking even under extreme temperature stress.

What about hygiene and moisture resistance?

Polystyrene absorbs very little moisture, does not support mold, fungus, or bacteria growth.

How smooth are the finished walls?

The blocks have perfect geometry and tongue-and-groove joints, ensuring accurate and smooth pool walls.

Do I need professional builders?

No. The structure assembles like LEGO: blocks are manually placed, reinforced, and filled with concrete.

What are the dimensions and specs of the blocks?

- Block size: 250 × 1000 × 250 mm;

- Two 50 mm layers of polystyrene;

- EPS grade: 90 or 120 (demountable — up to 120);

- Concrete core: 150 mm (up to 450 mm in demountables);

- Concrete consumption: 0.13 m3/m2 (up to 0.45 m3/m2 in demountables).

How much water is lost through absorption?

Only 0.5% over 24 hours, proving the structure's excellent protection and water resistance.

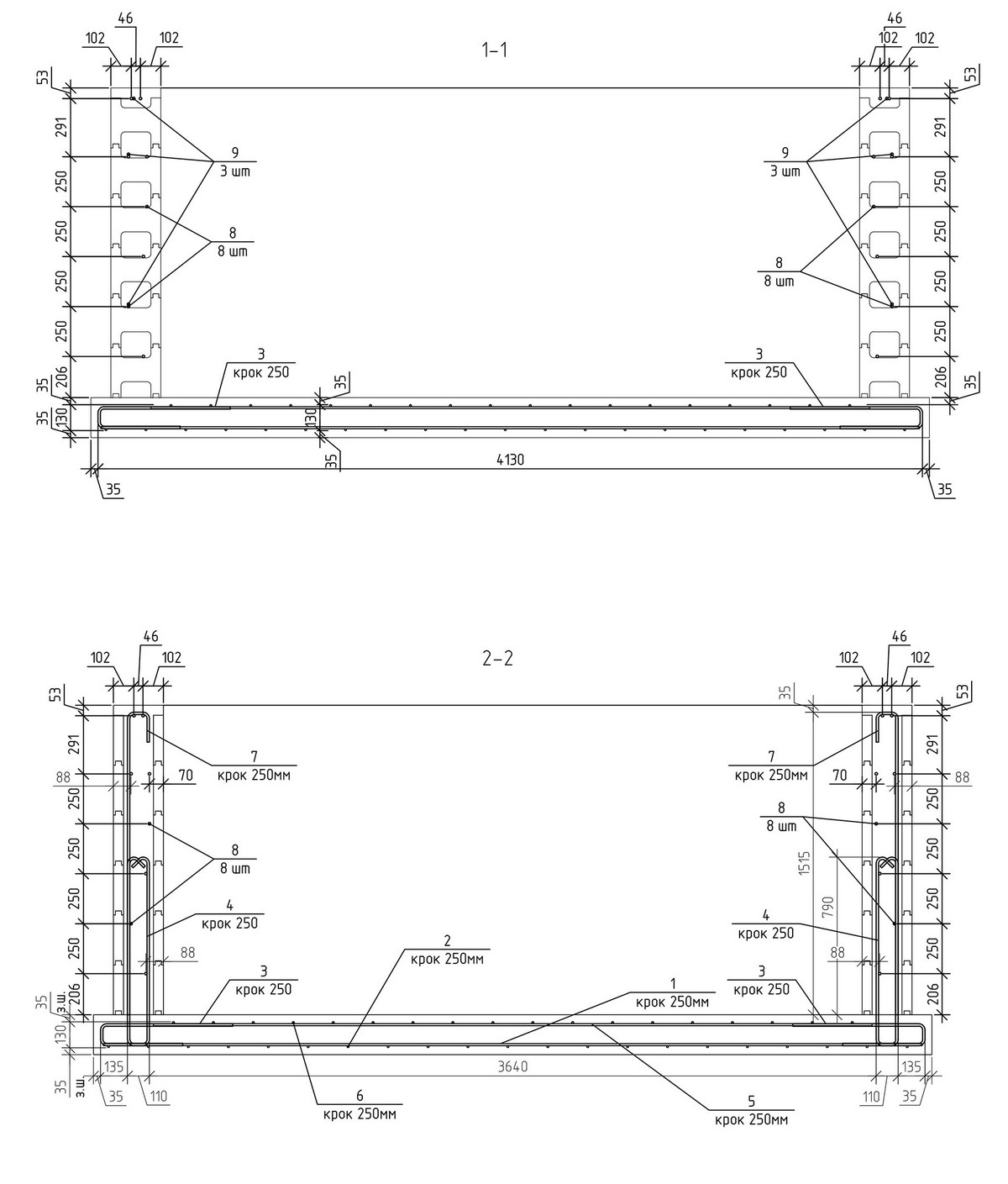

How is reinforcement installed?

Reinforcement meshes or cages are placed inside the blocks, then concrete is poured to create a solid monolithic pool shell.

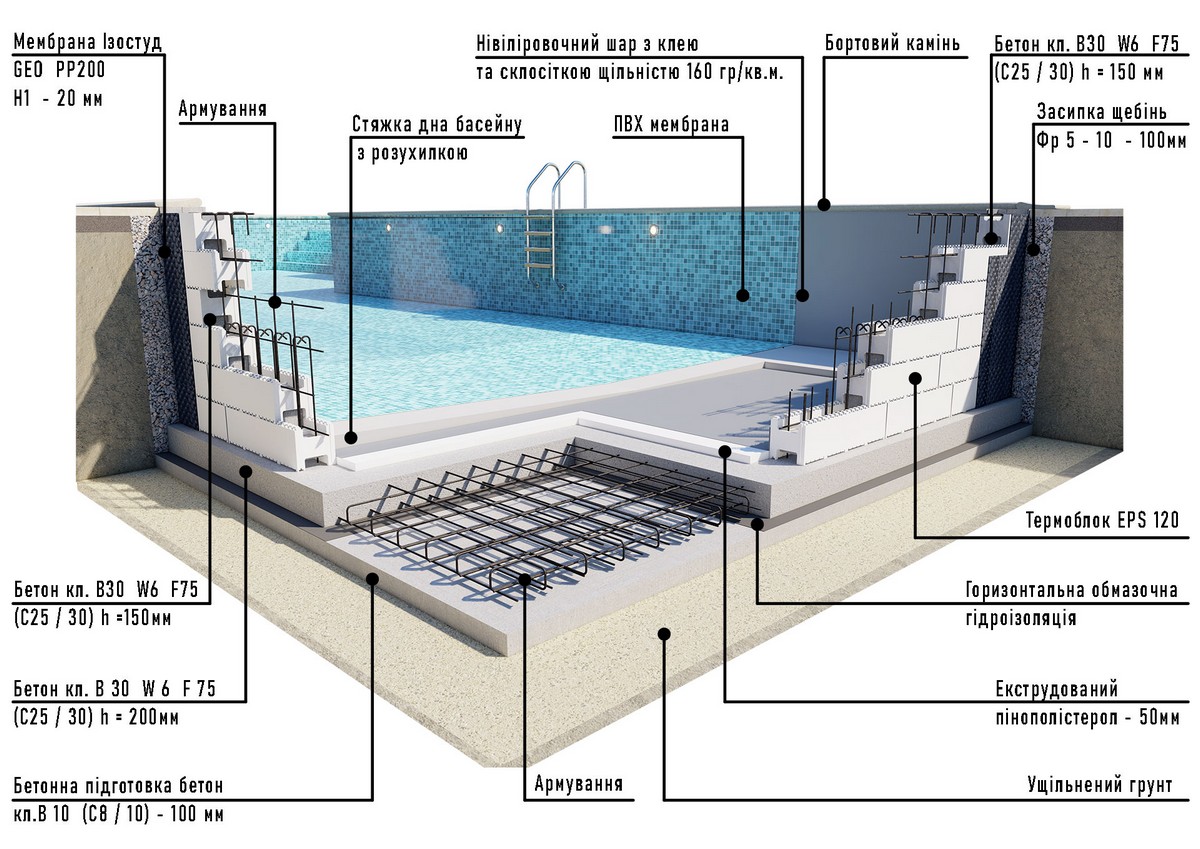

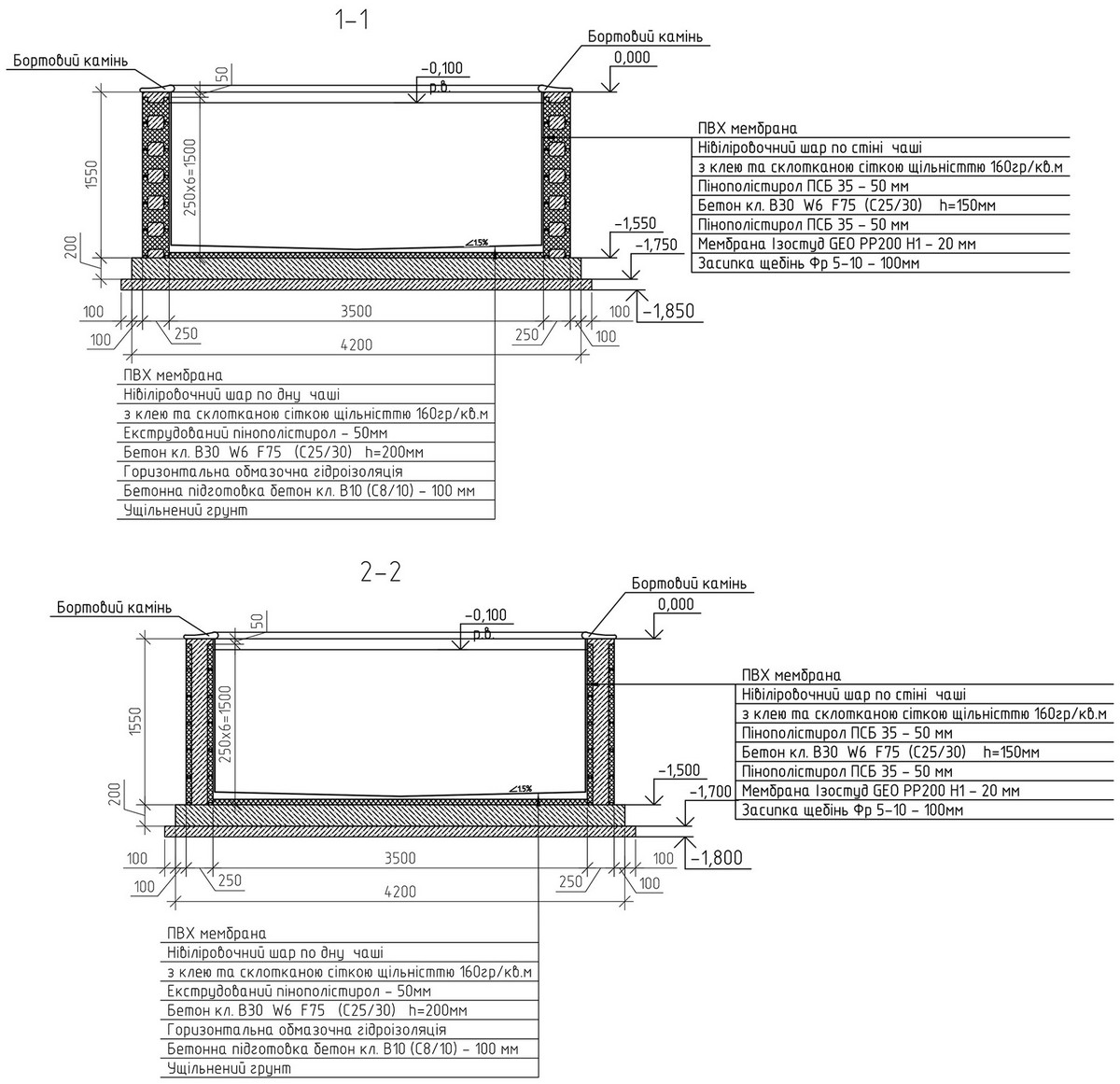

How is waterproofing and finishing done?

After concreting, waterproofing is applied using PVC membranes, coating systems, or penetrating sealants, followed by finishing with tiles or film depending on design requirements.

What is the step-by-step pool construction process?

- Excavation of the pit;

- Thermoblock assembly;

- Reinforcement placement;

- Concrete pouring;

- Waterproofing;

- Finishing the pool bowl.